Product Description

| OEM | 13505-17571 |

| Item Name | Belt Tensioner |

| MOQ | 100PCS |

| Warranty | 12 months |

| Price term | EXW HangZhou |

| Delivery time | According to your order |

| Size | OEM Standard Size |

| Warranty: | a Year |

|---|---|

| OE Number: | 13505-17020 |

| Item Name: | Belt Tensioner Pulley |

| Price Item: | EXW |

| Quality: | Class a |

| Estimated Weigh: | About 0.1kg |

| Customization: |

Available

| Customized Request |

|---|

What is the role of belt tensioner materials and coatings in performance and longevity?

Belt tensioner materials and coatings play a crucial role in the performance and longevity of belt tensioners. The choice of materials and coatings directly impacts the tensioner's ability to withstand the forces and loads encountered in belt-driven systems, resist wear and corrosion, and maintain consistent performance over time. Here's a detailed explanation of the role of belt tensioner materials and coatings in performance and longevity:

- Strength and Durability:

- Wear Resistance:

- Corrosion Resistance:

- Friction Reduction:

- Temperature Stability:

- Lubrication Enhancement:

- Noise and Vibration Damping:

The materials used in belt tensioners need to possess high strength and durability to withstand the mechanical stresses and loads imposed on them. Tensioner components are subjected to continuous movement and contact with the belt, which can lead to wear, fatigue, and potential failure. High-strength materials, such as hardened steels or alloys, are commonly used to ensure the tensioner's structural integrity and longevity.

Belt tensioners are exposed to friction and wear as they come into contact with the belt during operation. Materials with excellent wear resistance properties, such as hardened surfaces or wear-resistant coatings, are employed to minimize the wear rate and extend the tensioner's lifespan. These materials and coatings help maintain optimal contact between the tensioner and the belt, reducing the risk of belt slippage and premature failure.

In certain environments, belt tensioners may be exposed to corrosive substances, moisture, or contaminants, which can lead to corrosion and degradation of the tensioner components. Corrosion-resistant materials, such as stainless steel or corrosion-resistant alloys, are often utilized to protect the tensioner against corrosive elements. Additionally, coatings like zinc plating or other protective finishes can be applied to enhance the tensioner's corrosion resistance.

Reducing friction between the tensioner and the belt is essential for minimizing wear and maintaining consistent tension. Materials or coatings with low friction coefficients can help reduce the frictional forces and energy losses associated with the tensioner's operation. By reducing friction, these materials and coatings contribute to improved efficiency, reduced heat generation, and increased longevity of the tensioner and the entire belt-driven system.

Belt tensioners are exposed to a wide range of operating temperatures, including both high and low extremes. Materials with good temperature stability and resistance to thermal degradation are essential for reliable tensioner performance. Heat-resistant alloys, high-temperature plastics, or thermal barrier coatings may be utilized to ensure that the tensioner maintains its mechanical properties and functionality under elevated temperatures.

Some tensioner materials or coatings are designed to enhance lubrication and reduce friction between moving parts. They may have self-lubricating properties or be compatible with specific lubricants used in the belt-driven system. These materials and coatings help reduce wear, heat generation, and the need for external lubrication, contributing to improved performance and extended longevity of the tensioner.

Belt tensioners can generate noise and vibration during operation, which can affect the comfort and performance of the belt-driven system. Certain materials or coatings can help dampen vibrations and reduce noise levels, improving the overall system's performance and minimizing potential issues associated with excessive noise or vibrations.

In summary, the choice of belt tensioner materials and coatings is critical for ensuring optimal performance and longevity. Materials with high strength and durability, wear resistance, corrosion resistance, friction reduction, temperature stability, lubrication enhancement, and noise/vibration damping properties contribute to the tensioner's ability to withstand the operational demands of belt-driven systems. By selecting appropriate materials and coatings, manufacturers can enhance the reliability, durability, and overall efficiency of belt tensioners, leading to extended service life and improved performance of the belt-driven systems they are used in.

Can you provide examples of products or equipment that rely on belt tensioners for efficient operation?

Yes, there are numerous products and equipment that rely on belt tensioners for efficient operation. Belt tensioners play a crucial role in maintaining optimal tension in belts, ensuring proper power transmission, minimizing slippage, and extending the lifespan of belts and associated components. Here are some examples of products and equipment that commonly utilize belt tensioners:

- Automotive Engines:

- Industrial Machinery:

- Agricultural Equipment:

- HVAC Systems:

- Pumping Systems:

- Power Tools:

- Exercise Equipment:

Belt tensioners are essential components in automotive engines. They are commonly used in the serpentine belt system, which drives various engine accessories such as the alternator, power steering pump, air conditioning compressor, and water pump. Tensioners ensure that the serpentine belt remains properly tensioned to prevent belt slippage and maintain efficient operation of these engine accessories.

A wide range of industrial machinery relies on belt tensioners for efficient operation. Examples include conveyor systems, packaging equipment, printing machines, textile machinery, and woodworking machinery. Belt tensioners in these applications maintain proper tension in belts that drive moving components, ensuring consistent power transmission, smooth operation, and reduced downtime due to belt-related issues.

In agricultural equipment such as tractors, combines, and harvesters, belt tensioners are critical for the proper operation of belts that drive components like the fan, water pump, and various harvesting mechanisms. Tensioners help maintain optimal belt tension, preventing slippage and ensuring efficient power delivery to these vital agricultural machinery components.

Heating, ventilation, and air conditioning (HVAC) systems rely on belt tensioners for efficient operation of the blower fans, compressors, and pumps. Belt tensioners in HVAC systems maintain the correct tension in belts, ensuring proper airflow, efficient cooling or heating, and reliable operation of the HVAC equipment.

Pumping systems, including water pumps, fuel pumps, and hydraulic pumps, often incorporate belt tensioners to maintain the optimal tension in belts. These tensioners contribute to efficient power transmission, preventing slippage and ensuring reliable fluid transfer in various industries, such as water treatment, oil and gas, and construction.

Belt-driven power tools, such as belt sanders, grinders, and lathes, rely on belt tensioners to maintain proper tension in the belts that drive the tool's rotating components. Tensioners in power tools ensure efficient power transfer, reduce belt wear, and enhance the tool's overall performance.

Many types of exercise equipment, including treadmills, stationary bikes, and rowing machines, incorporate belt tensioners to ensure smooth and efficient operation. These tensioners maintain proper tension in the belts that drive the equipment's resistance mechanisms, allowing users to achieve desired workout intensity and providing a consistent exercise experience.

These are just a few examples of the wide range of products and equipment that rely on belt tensioners for efficient operation. Belt tensioners are used in various industries and applications where belt-driven systems are employed, ensuring reliable power transmission, minimizing belt wear, and contributing to overall system performance and longevity.

Can you describe the various types of belt tensioners, such as automatic or manual tensioners?

There are various types of belt tensioners available, each designed to fulfill specific requirements in maintaining belt tension. Here's a description of the different types of belt tensioners:

- Manual Belt Tensioners:

- Automatic Belt Tensioners:

- Hydraulic Belt Tensioners:

- Eccentric Belt Tensioners:

- Idler Pulley Tensioners:

Manual belt tensioners are the most basic type and require manual adjustment to set and maintain the desired tension. They typically consist of an adjustable arm or bracket that can be moved to increase or decrease the tension in the belt. Manual tensioners are commonly used in applications where tension adjustments are infrequent or can be easily accessed for manual adjustment. They are simple, cost-effective, and widely used in various industries.

Automatic belt tensioners, also known as self-adjusting or spring-loaded tensioners, are designed to maintain the proper tension automatically. They incorporate a spring mechanism that applies constant tension to the belt, compensating for belt elongation and wear over time. Automatic tensioners are commonly used in applications where frequent manual adjustments are impractical or where consistent tension control is essential. They provide convenience, minimize maintenance requirements, and ensure optimal tension without the need for manual intervention.

Hydraulic belt tensioners utilize hydraulic pressure to maintain belt tension. They consist of a hydraulic cylinder or piston that applies force to the tensioner arm, adjusting the tension in the belt. Hydraulic tensioners are commonly used in applications with high load requirements or variable operating conditions. They provide precise tension control, can compensate for changes in temperature and load, and are often employed in heavy-duty industrial machinery and automotive applications.

Eccentric belt tensioners use an eccentric mechanism to adjust the tension in the belt. They typically feature an eccentric pulley or roller that can be rotated to increase or decrease the tension. Eccentric tensioners are commonly used in applications where precise tension adjustments are required, such as high-performance engines or systems with specific belt tension specifications. They offer fine-tuning capabilities and are often found in automotive racing, performance tuning, and specialized machinery.

Idler pulley tensioners, also known as fixed tensioners or idler pulley assemblies, are a type of belt tensioner that utilizes an idler pulley to maintain tension. They are typically positioned on the slack side of the belt, providing guidance and tension control. Idler pulley tensioners are commonly used in applications where a fixed tension is desired, and the tensioning capability is provided by other components in the system, such as an automatic tensioner or an adjustable drive pulley.

In addition to these types, there are also specialized belt tensioners designed for specific applications or industries, such as torsional vibration dampers used in automotive engines to reduce vibrations, or belt tensioners with built-in dampening mechanisms to minimize noise in certain applications.

Overall, the choice of belt tensioner depends on factors such as the application requirements, load conditions, frequency of tension adjustments, and the desired level of automation and control. Selecting the appropriate type of belt tensioner is crucial to maintaining optimal belt tension and ensuring the efficient and reliable operation of belt-driven systems.

editor by CX 2023-11-16

China Good quality for Audi Belt Tensioner 06b109243b 06b109243e a wheel and axle simple machine

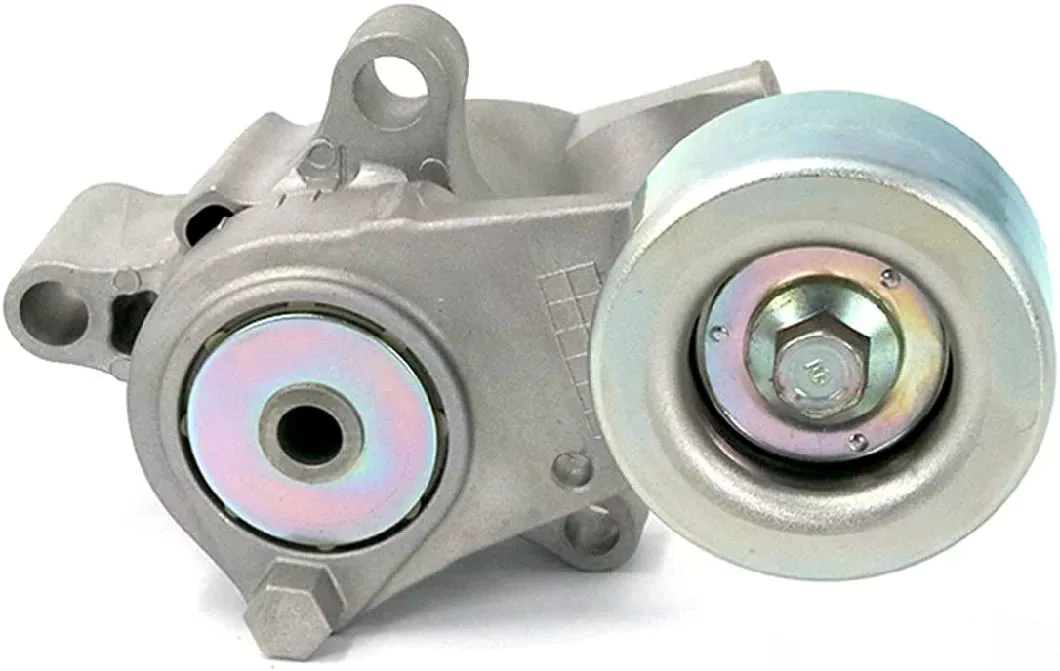

Product Description

AUDI BELT TENSIONER 06B109243B 06B109243E

OEM:06B109243B 06B109243E

REF NO:

FEBI 18554

INA 53157120

SKF VKM11018

ATB2145

RUVILLE 55496

GATES T43018

SIZE:72*30.8

FIT FOR

AUDI A4 1.8T/2.0

AUDI A6 1.8T/2.0

Product Parameters

|

OEM NO. |

06B109243B 06B109243E |

| Application | AUDI |

|

Place of Origin |

ZHangZhoug, China |

|

Material |

Aluminium |

| Product Name |

Belt Tensioner |

|

Reference NO. |

|

|

Packing |

Neutral Packing |

|

SHIPPING TERM |

Sea/Air |

|

Quality |

100%tested |

|

Size |

same as OEM |

| After-sales Service: | 1 Year |

|---|---|

| Warranty: | 1 Year |

| Certification: | CCC, ISO9001, TS16949 |

| Samples: |

US$ 30/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

| Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Can you provide guidance on the selection and sizing of belt tensioners for specific belt applications?

When selecting and sizing belt tensioners for specific belt applications, several factors need to be considered to ensure optimal performance and longevity. Here's a detailed guidance on the selection and sizing of belt tensioners:

- Belt Type and Size:

- System Requirements:

- Tensioner Type:

- Tensioner Design and Mounting:

- Tensioner Load Capacity:

- Environmental Considerations:

- Manufacturer Recommendations:

Start by identifying the type and size of the belt used in the application. Belts can vary in terms of width, length, profile (V-belt, timing belt, etc.), and construction material (rubber, polyurethane, etc.). The tensioner should be compatible with the specific belt type and size to ensure proper fit and functionality.

Consider the requirements of the belt-driven system. Evaluate factors such as the desired tension level, operating speed, load conditions, and environmental factors. The tensioner should be capable of providing the required tension force while accommodating the system's operating parameters.

Choose the appropriate tensioner type based on the application's needs. Common types include automatic tensioners, idler pulley tensioners, spring-loaded tensioners, and hydraulic tensioners. Each type has its advantages and limitations, so select the one that best suits the specific belt application.

Consider the design and mounting requirements of the tensioner. Evaluate the space availability, mounting configuration, and alignment with other components in the belt drive system. Some tensioners offer adjustable mounting positions or different design variations to accommodate various installation scenarios.

Check the load capacity of the tensioner to ensure it can handle the expected loads and forces in the belt system. Consider factors such as the belt tension, shock loads, and dynamic forces. The tensioner should have adequate load capacity to prevent premature wear or failure under normal operating conditions.

Assess the environmental conditions in which the tensioner will operate. Factors such as temperature extremes, moisture, dust, chemicals, and exposure to UV radiation can impact the tensioner's performance and durability. Choose a tensioner that is designed to withstand the specific environmental challenges of the application.

Refer to the manufacturer's guidelines and recommendations for selecting and sizing the tensioner. Manufacturers often provide technical data, specifications, and selection guides that assist in choosing the appropriate tensioner for specific belt applications. Follow their recommendations to ensure compatibility and optimal performance.

It is important to note that the selection and sizing of belt tensioners may require technical expertise and consideration of specific application requirements. If in doubt, consult with belt tensioner manufacturers or industry experts who can provide further guidance based on their knowledge and experience.

In summary, when selecting and sizing belt tensioners for specific belt applications, consider the belt type and size, system requirements, tensioner type, design and mounting, load capacity, environmental conditions, and manufacturer recommendations. By carefully evaluating these factors, you can choose a suitable tensioner that ensures proper tensioning, reliable operation, and extended belt life in the belt-driven system.

How do belt tensioners contribute to reducing vibrations and noise in machinery?

Belt tensioners play a significant role in reducing vibrations and noise in machinery. They contribute to the smooth operation of belt-driven systems by maintaining proper belt tension, which helps minimize dynamic belt movements and associated vibrations. Here's a detailed explanation of how belt tensioners contribute to reducing vibrations and noise:

- Stabilizing Belt Movement:

- Minimizing Belt Resonance:

- Damping Vibrations:

- Reducing Belt Slippage:

- Minimizing Belt Flapping:

- Promoting Stable Rotational Motion:

Proper tensioning of belts helps stabilize their movement during operation. When belts are under the correct tension, they are less likely to experience excessive lateral or longitudinal movements. These movements, known as belt flutter or belt whip, can cause vibrations and noise. Belt tensioners apply the necessary force to keep the belt properly tensioned, preventing excessive movement and reducing the generation of vibrations and associated noise.

Belt resonance refers to the phenomenon where a belt's natural frequency coincides with the operating speed of the system, leading to excessive vibrations and noise. Proper belt tensioning helps to minimize belt resonance by ensuring that the belt operates within its stable tension range. By avoiding resonance conditions, belt tensioners contribute to a smoother operation, reducing vibrations and noise caused by belt resonance.

Belt tensioners can also act as vibration dampers. They absorb or dissipate some of the vibrations generated by the rotating components connected by the belt. The tensioner's design may incorporate features such as dampening springs or rubber elements that help absorb and dampen vibrations. This damping effect reduces the transmission of vibrations through the belt, resulting in reduced overall vibration levels and associated noise.

Improper tensioning can lead to belt slippage, where the belt slips on the pulleys or sheaves instead of maintaining a firm grip. Belt slippage generates friction and can cause vibrations and noise. Belt tensioners ensure that the belt remains properly tensioned, minimizing the risk of slippage and reducing associated vibrations and noise.

When belts are not properly tensioned, they can exhibit flapping or flailing movements, especially at higher speeds. These movements can generate vibrations and noise. Belt tensioners help maintain the correct tension, keeping the belt taut and preventing excessive flapping. By minimizing belt flapping, tensioners contribute to a smoother operation with reduced vibrations and noise.

A properly tensioned belt ensures stable rotational motion of the pulleys or sheaves it is driving. When belts are under the correct tension, they maintain a consistent grip on the pulleys, preventing sudden slips or variations in rotational motion. This stability in rotational motion helps minimize vibrations and associated noise, resulting in smoother and quieter machinery operation.

In summary, belt tensioners contribute to reducing vibrations and noise in machinery by stabilizing belt movement, minimizing belt resonance, damping vibrations, reducing belt slippage, minimizing belt flapping, and promoting stable rotational motion. By maintaining proper belt tension, tensioners help achieve smoother operation, reduce vibrations, and minimize the generation and transmission of noise, resulting in improved comfort, efficiency, and reliability of the machinery.

How do belt tensioners differ from other components in maintaining belt tension?

Belt tensioners play a distinct role in maintaining belt tension compared to other components in belt drive systems. Here's a detailed explanation of how belt tensioners differ from other components:

1. Tension Adjustment:

Belt tensioners are specifically designed to provide an adjustable means of maintaining the proper tension in the belt. They are equipped with mechanisms such as springs, adjustable arms, or brackets that allow for easy tension adjustment. Other components in belt drive systems, such as pulleys or idlers, do not have this specific functionality and rely on external means, such as manual adjustment or fixed positioning, to maintain tension.

2. Active Tension Control:

Belt tensioners actively control and apply force to the belt to maintain tension. They are designed to compensate for belt elongation, thermal expansion, and other factors that can affect tension over time. By applying the appropriate tension, belt tensioners help to prevent belt slippage and maintain efficient power transmission. In contrast, other components, such as fixed pulleys or idlers, do not actively control tension and rely on the initial tension set during installation.

3. Dynamic Tension Compensation:

Belt tensioners are capable of dynamically adjusting the tension in response to changes in operating conditions. For example, in automotive applications, belt tensioners can compensate for variations in engine speed, temperature fluctuations, and belt wear. They can adapt to these changes and maintain the optimal tension level. Other components, such as fixed pulleys or idlers, do not possess this dynamic tension adjustment capability.

4. Vibration and Noise Damping:

Belt tensioners often incorporate features to dampen vibrations and reduce noise in the belt drive system. They act as shock absorbers, absorbing and dissipating vibrations, which helps to minimize belt flutter and reduce noise levels. Other components, such as fixed pulleys or idlers, do not typically have built-in vibration and noise damping properties.

5. Positioning on Slack Side:

Belt tensioners are typically positioned on the slack side of the belt, between the driving pulley and the driven pulley. This positioning allows them to apply tension to the belt where it is needed most, helping to maintain proper engagement and prevent slippage. In contrast, other components, such as fixed pulleys or idlers, are positioned on the tight side of the belt and primarily serve to guide and support the belt.

6. Component Integration:

Belt tensioners are standalone components that are specifically designed for tensioning belts. They are often integrated into the belt drive system as a separate unit, allowing for easy installation, adjustment, and replacement. Other components, such as pulleys or idlers, serve different functions in the system and may be integrated into other mechanisms or structures.

In summary, belt tensioners differ from other components in belt drive systems in their ability to provide adjustable tension control, dynamic tension compensation, vibration and noise damping capabilities, specific positioning on the slack side of the belt, and as standalone components designed solely for tensioning belts. These features make belt tensioners essential for maintaining optimal tension and ensuring the efficient and reliable operation of belt drive systems.

editor by CX 2023-11-14

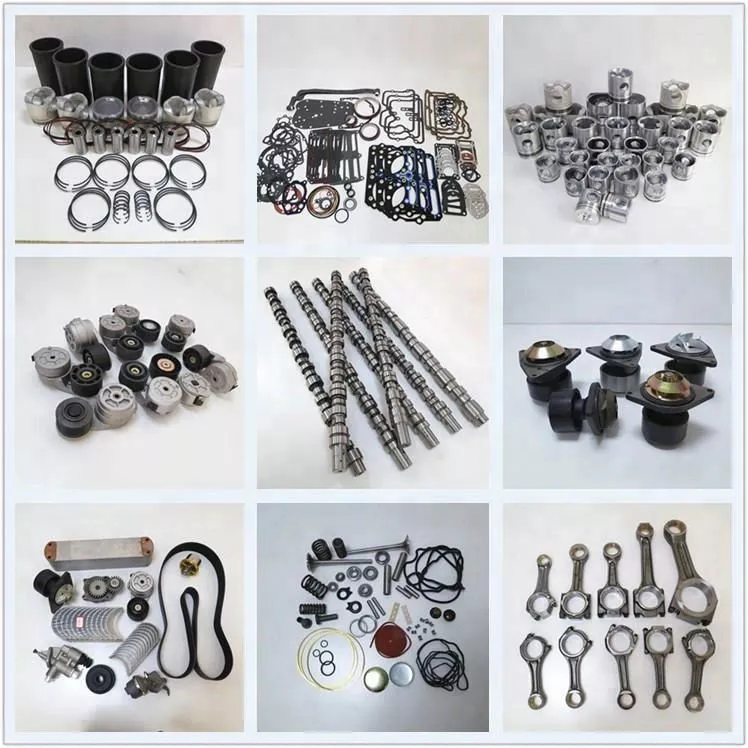

China manufacturer D6d Belt Tensioner for CZPT CZPT CZPT Excavator Engine Tensioner cv axle repair

Product Description

D6D belt tensioner for Caterpillar CZPT CZPT excavator engine tensioner

Product Description

The tension pulley is mainly composed of fixed shell, tension arm, wheel body, torsion spring, rolling bearing and spring sleeve.It can automatically adjust the tension according to the different tightness of the belt, making the transmission system stable,safe and reliable.

The tension pulley is a vulnerable part of automobile and other spare parts. The belt is easy to wear after a long time. The belt groove will be elongated after being worn deeply and narrowly. The tension pulley can be adjusted automatically according to the wear degree of the belt through the hydraulic unit or damping spring. In addition, with the tension pulley, the leather belt runs more smoothly, has less noise, and can prevent slipping

The tension wheel is a routine maintenance item, which needs to be replaced after 60000-80000 km. Usually, if there is abnormal howling at the front end of the engine or the position of the tension mark of the tension wheel deviates too much from the center, it means that the tension is insufficient. It is recommended to replace the belt, tension pulley, idler and generator single pulley in a unified way when the distance is 60000-80000 km (or when the front-end accessory system makes abnormal noise).

D6D belt tensioner for Caterpillar CZPT CZPT excavator engine tensioner

Detailed Photos

To maintain proper belt tension, avoid belt slippage, and compensate for elongation due to belt wear and age, the tensioner pulley requires a certain amount of torque. When a belt tensioner is running, the moving belt can cause the tensioner to vibrate, causing premature belt and tensioner wear. Therefore, a resistance mechanism is added to the tensioner. However, since there are many parameters affecting the torque and resistance of the tensioning wheel, and the influence of each parameter is not the same, the relationship between the components of the tensioning wheel and the torque and resistance is very complicated. The change of torque directly affects the change of resistance, which is the main influencing factor of resistance. The main factor affecting the torque is the parameters of the torsion spring.

D6D belt tensioner for Caterpillar CZPT CZPT excavator engine tensioner

Specification

|

item |

value |

|

Place of Origin |

ZheJiang ,China |

|

Brand Name |

CARRUCHI |

|

Model Number |

D6D |

|

Product name |

DHL UPS FEDEX EMS SEA |

|

Quality |

High-Quality |

|

Packing |

Carton |

|

MOQ |

10pcs |

|

Warranty |

3 Months |

|

Truck Model |

Caterpillar CZPT CZPT excavator |

|

PAYMENT |

T/T |

|

DELIVERY TIME |

3-7 Days |

|

WEIGHT |

2KG |

|

Shipping |

DHL UPS FEDEX EMS SEA |

D6D belt tensioner for Caterpillar CZPT CZPT excavator engine tensioner

Packaging & Shipping

1.To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

Details: Our packing uses export wooden cases, plastic boxes, cartons or pallets. All the package are very strong, the wooden box is firmly bound, the package is covered with a waterproof film to prevent water or damage during transportation.Before packing, we can also stick corresponding labels and shipping marks according to your needs. All our goods are well packed.

2. According to the quantity, we can use express delivery, air transportation or CZPT transportation, automobile transportation, railway transportation, etc.

we have our own freight forwarders, and we can also use the designated freight forwarders of customers, which can meet various delivery requirements of customers, such as EXW, FOB, CIF, etc.It can also be exported from many ports in China. Such as HangZhou port, HangZhou port, HangZhou port, ZheJiang port, HangZhou River and HangZhou in China.

3. We can also send the goods by express if the customers have less goods.

According to customer's request, we can use express.such as DHL, TNT, EMS, FedEx, etc. the delivery time is 3-7. Safe, fast and convenient. It's also a good choice for you.

Certifications

HangZhou CZPT International Trade Co., Ltd. was established in 2003. It has been engaged in the export of auto parts and construction machinery parts for 8 years. Our main business is to export truck parts and construction machinery parts to Russia,Europe and Southeast Asia, such as SINOTRUK, Shaanqi, Xihu (West Lake) Dis., XCMG, Shantui, JAC, Cummins, JCB, caterpillar, Isuzu,Yanmar, lgmg, CZPT The company has its own warehouse in HangZhou, covering an area of 2000 square meters, and has a lot of inventory,and has the ability to quickly collect and deliver accessories. Warehouse inventory is huge, and many kinds, to meet your various needs.We always adhere to the quality of products as the core, to serve customers for the purpose. Hope to be CZPT to better communicate with friends from all over the world.

Company Profile

Carman International Trade Co, Ltd. Ia an import and export company that founded in 2013, setting up with the approval of Ministry of Commerce. Based on good faith and pursuit of mutual benefit, we supply Diesel engine spare parts for many domestic retailers and wholesalers, what's more, our products are sold well to Japan, Korean, Malaysia, Indonesia, Germany, Russian, Turkey,Iran,Brazil, Peru, as well as other countries in the Middle East, and Africa etc.The company has a number of diligent and advanced marketing and management experience of employees, for our customers to provide more professional, humane services.

At the same time, the company vigorously develop advantageous products, integration and optimization of sales channels, in order to ensure quality at the same time, but also for dealers to retain a more careful profit margins. The company has innovative sales concept, high standards of product quality management as the basis, market as a guide, customer satisfaction as the criterion, the implementation of standardized customer service, forming a unique culture of high-quality service, customer service will fully implement the "customer guide, service value-added" strategy, in line with people-oriented, abide by the credibility, brand management, quality first, user first principle, so that more customers enjoy intimate service.

FAQ

1. who are we?

We are based in ZheJiang , China, start from 2013,sell to Mid East(50.00%),Eastern Europe(20.00%),Eastern Asia(10.00%),South America(7.00%),Southeast Asia(5.00%),Africa(4.00%),North America(3.00%),Domestic Market(00.00%). There are total about 11-50 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Heavy Truck Parts and Construction Machinery Parts/Filter/Turbocharger/Clutch Disc/Clutch Cover/Water Pump/Truck Chassis Parts

4. why should you buy from us not from other suppliers?

.,,..

5.?

:3-7

:T/T

:T/T

:

| After-sales Service: | 3 Months |

|---|---|

| Warranty: | 3 Months |

| Certification: | TS16949 |

| Samples: |

US$ 450/Piece

1 Piece(Min.Order) | Order Sample The sample is consistent with the sold product

|

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Can you provide guidance on the selection and sizing of belt tensioners for specific belt applications?

When selecting and sizing belt tensioners for specific belt applications, several factors need to be considered to ensure optimal performance and longevity. Here's a detailed guidance on the selection and sizing of belt tensioners:

- Belt Type and Size:

- System Requirements:

- Tensioner Type:

- Tensioner Design and Mounting:

- Tensioner Load Capacity:

- Environmental Considerations:

- Manufacturer Recommendations:

Start by identifying the type and size of the belt used in the application. Belts can vary in terms of width, length, profile (V-belt, timing belt, etc.), and construction material (rubber, polyurethane, etc.). The tensioner should be compatible with the specific belt type and size to ensure proper fit and functionality.

Consider the requirements of the belt-driven system. Evaluate factors such as the desired tension level, operating speed, load conditions, and environmental factors. The tensioner should be capable of providing the required tension force while accommodating the system's operating parameters.

Choose the appropriate tensioner type based on the application's needs. Common types include automatic tensioners, idler pulley tensioners, spring-loaded tensioners, and hydraulic tensioners. Each type has its advantages and limitations, so select the one that best suits the specific belt application.

Consider the design and mounting requirements of the tensioner. Evaluate the space availability, mounting configuration, and alignment with other components in the belt drive system. Some tensioners offer adjustable mounting positions or different design variations to accommodate various installation scenarios.

Check the load capacity of the tensioner to ensure it can handle the expected loads and forces in the belt system. Consider factors such as the belt tension, shock loads, and dynamic forces. The tensioner should have adequate load capacity to prevent premature wear or failure under normal operating conditions.

Assess the environmental conditions in which the tensioner will operate. Factors such as temperature extremes, moisture, dust, chemicals, and exposure to UV radiation can impact the tensioner's performance and durability. Choose a tensioner that is designed to withstand the specific environmental challenges of the application.

Refer to the manufacturer's guidelines and recommendations for selecting and sizing the tensioner. Manufacturers often provide technical data, specifications, and selection guides that assist in choosing the appropriate tensioner for specific belt applications. Follow their recommendations to ensure compatibility and optimal performance.

It is important to note that the selection and sizing of belt tensioners may require technical expertise and consideration of specific application requirements. If in doubt, consult with belt tensioner manufacturers or industry experts who can provide further guidance based on their knowledge and experience.

In summary, when selecting and sizing belt tensioners for specific belt applications, consider the belt type and size, system requirements, tensioner type, design and mounting, load capacity, environmental conditions, and manufacturer recommendations. By carefully evaluating these factors, you can choose a suitable tensioner that ensures proper tensioning, reliable operation, and extended belt life in the belt-driven system.

How do belt tensioners contribute to reducing vibrations and noise in machinery?

Belt tensioners play a significant role in reducing vibrations and noise in machinery. They contribute to the smooth operation of belt-driven systems by maintaining proper belt tension, which helps minimize dynamic belt movements and associated vibrations. Here's a detailed explanation of how belt tensioners contribute to reducing vibrations and noise:

- Stabilizing Belt Movement:

- Minimizing Belt Resonance:

- Damping Vibrations:

- Reducing Belt Slippage:

- Minimizing Belt Flapping:

- Promoting Stable Rotational Motion:

Proper tensioning of belts helps stabilize their movement during operation. When belts are under the correct tension, they are less likely to experience excessive lateral or longitudinal movements. These movements, known as belt flutter or belt whip, can cause vibrations and noise. Belt tensioners apply the necessary force to keep the belt properly tensioned, preventing excessive movement and reducing the generation of vibrations and associated noise.

Belt resonance refers to the phenomenon where a belt's natural frequency coincides with the operating speed of the system, leading to excessive vibrations and noise. Proper belt tensioning helps to minimize belt resonance by ensuring that the belt operates within its stable tension range. By avoiding resonance conditions, belt tensioners contribute to a smoother operation, reducing vibrations and noise caused by belt resonance.

Belt tensioners can also act as vibration dampers. They absorb or dissipate some of the vibrations generated by the rotating components connected by the belt. The tensioner's design may incorporate features such as dampening springs or rubber elements that help absorb and dampen vibrations. This damping effect reduces the transmission of vibrations through the belt, resulting in reduced overall vibration levels and associated noise.

Improper tensioning can lead to belt slippage, where the belt slips on the pulleys or sheaves instead of maintaining a firm grip. Belt slippage generates friction and can cause vibrations and noise. Belt tensioners ensure that the belt remains properly tensioned, minimizing the risk of slippage and reducing associated vibrations and noise.

When belts are not properly tensioned, they can exhibit flapping or flailing movements, especially at higher speeds. These movements can generate vibrations and noise. Belt tensioners help maintain the correct tension, keeping the belt taut and preventing excessive flapping. By minimizing belt flapping, tensioners contribute to a smoother operation with reduced vibrations and noise.

A properly tensioned belt ensures stable rotational motion of the pulleys or sheaves it is driving. When belts are under the correct tension, they maintain a consistent grip on the pulleys, preventing sudden slips or variations in rotational motion. This stability in rotational motion helps minimize vibrations and associated noise, resulting in smoother and quieter machinery operation.

In summary, belt tensioners contribute to reducing vibrations and noise in machinery by stabilizing belt movement, minimizing belt resonance, damping vibrations, reducing belt slippage, minimizing belt flapping, and promoting stable rotational motion. By maintaining proper belt tension, tensioners help achieve smoother operation, reduce vibrations, and minimize the generation and transmission of noise, resulting in improved comfort, efficiency, and reliability of the machinery.

Are there specific belt tensioner designs for different applications, like automotive or industrial equipment?

Yes, there are specific belt tensioner designs tailored for different applications, including automotive and industrial equipment. Manufacturers develop specialized belt tensioners to meet the unique requirements and operating conditions of various industries. Here's a detailed explanation of specific belt tensioner designs for different applications:

- Automotive Belt Tensioners:

- Industrial Belt Tensioners:

- Agricultural Belt Tensioners:

- HVAC and Refrigeration Belt Tensioners:

- Specialized Belt Tensioners:

Belt tensioners used in automotive applications are designed with features that address the specific needs of the automotive industry. They are typically compact, lightweight, and engineered to withstand the demanding conditions found in vehicle engines. Automotive belt tensioners often incorporate automatic tensioning mechanisms, such as spring-loaded or hydraulic designs, to provide continuous tension control and compensate for belt elongation and wear over time. They also incorporate features like torsional vibration dampers to minimize vibrations and noise. Additionally, automotive belt tensioners undergo rigorous testing to meet industry standards and ensure reliable performance in diverse driving conditions.

Industrial belt tensioners are designed to meet the requirements of heavy-duty applications in various industries, such as manufacturing, material handling, mining, and construction. These tensioners are built to withstand high loads, harsh environments, and extended operating hours. Industrial belt tensioners often feature robust construction using durable materials like cast iron or steel. They may incorporate automatic tensioning mechanisms, hydraulic systems, or eccentric designs to provide precise tension control and adaptability to changing operating conditions. Industrial belt tensioners also come in a range of sizes and configurations to accommodate different belt sizes and drive systems used in industrial machinery.

Agricultural equipment, such as tractors, combines, and harvesters, have specific belt tensioner designs suited for the demanding conditions encountered in farming operations. Agricultural belt tensioners are designed to withstand dust, debris, and exposure to outdoor elements. They often incorporate automatic tensioning mechanisms with robust spring-loaded systems to compensate for belt wear and maintain optimal tension during extended periods of use. These tensioners are engineered to provide reliable performance in agricultural machinery, contributing to efficient power transmission and reduced maintenance requirements.

Belt tensioners used in HVAC and refrigeration systems are designed to ensure reliable and efficient operation of fans, blowers, compressors, and pumps. These tensioners are typically compact and incorporate automatic tensioning mechanisms to maintain consistent belt tension under varying operating conditions. They may also include features like vibration dampening to reduce noise and enhance system performance. HVAC and refrigeration belt tensioners are engineered to meet the specific requirements of cooling and ventilation systems, contributing to energy efficiency and prolonged equipment lifespan.

There are also specialized belt tensioners designed for specific applications or industries. For example, in the woodworking industry, belt tensioners with quick-release mechanisms are used to facilitate efficient belt changes. In the textile industry, belt tensioners with precise tension control are employed to ensure proper synchronization of moving parts. Marine propulsion systems utilize belt tensioners designed for marine environments, resistant to corrosion and capable of withstanding vibration and shock. These specialized tensioners are tailored to the specific needs of their respective industries, incorporating features and materials that optimize performance and durability.

Overall, the design of belt tensioners is influenced by the unique requirements of different applications and industries. By considering factors such as load capacity, environmental conditions, tension control mechanisms, and specific industry standards, manufacturers develop belt tensioners that are well-suited for their intended applications, ensuring optimal belt performance and system reliability.

editor by CX 2023-11-14

China Professional Triangular Multi-Wedge Belt Engine Belt Tensioner 51958007473 51958007446 51958007460 for Man Tgs supplier

Product Description

Product Description

| OuChai NO. | Oem NO. | Application | Size |

| OC9 0571 | 51958 519580 0571 0 | MAN | Standard |

1. We are a professional manufactory product belt tensioner for truck and passenger car.

2. Advantage:

1)Reliable and durable, Strict quality control.

2))FOB\CIF\C&F price.

3)Small MOQ.

4)Specialized in belt tensioner.

5)Wholesale for auto truck parts.

6)Supply package.

3. Packing:

1) OUCHAI packing

2) Neutral packing

3) customer request

4. Shipping:

1. By sea, DHL, FedEx, ect.

2. Within 15 days after receiving 30% deposit

About us

HangZhou OUCHAI TECHNOLOGY CO.,LTD is located in Kunyang Nailali Industrial Zone, Xihu (West Lake) Dis., HangZhou. Our factory is a professional manufacturer of producing belt tensioner with designing and selling.

Our company was founded in 2014, with RMB 3 million registered capital, and covers an area 2000 square meters. There are 30 workers in our factory, including 2 engineers and 6 technicians.

Our company fully implement IATF16949 quality management system and own the advanced production equipment, such as CNC lathe, punching machine, die-casting machine, assembly line and testing equipment.

Our products mainly exported to European, America and South East, and deeply praised by customers. We always adhere to the principle of "integrity is foundation, quality is first, CZPT cooperation" and we'll move forward all the way.

Detailed Photos

| After-sales Service: | 1year |

|---|---|

| Warranty: | 1year |

| Car Make: | Man |

| Samples: |

US$ 60/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

How do belt tensioners enhance the overall efficiency and lifespan of belts in various applications?

Belt tensioners play a crucial role in enhancing the overall efficiency and lifespan of belts in various applications. They are designed to maintain proper tension in the belt, ensuring optimal power transmission, minimizing slippage, and reducing wear. Here's a detailed explanation of how belt tensioners enhance efficiency and lifespan:

- Optimal Tension:

- Compensating for Belt Stretch:

- Reduced Slippage:

- Improved Belt Life:

- Reduced Maintenance:

- Noise and Vibration Reduction:

Belt tensioners are responsible for maintaining the correct tension in the belt. Proper tension is essential for efficient power transmission and preventing belt slippage. By applying the right amount of tension, belt tensioners ensure that the belt remains securely engaged with the pulleys, allowing for efficient transfer of power. This optimal tension minimizes energy losses, improves system efficiency, and reduces the risk of premature belt wear or failure due to inadequate tension.

Belts can stretch over time due to various factors such as normal wear, temperature changes, or load variations. Belt tensioners are designed to compensate for belt stretch by automatically adjusting the tension as needed. This feature helps maintain consistent belt tension and ensures proper power transmission, even as the belt elongates over its service life. By compensating for belt stretch, tensioners prevent slack in the belt, reduce the risk of belt jumping or misalignment, and extend the lifespan of the belt.

Slippage between the belt and the pulleys can lead to power loss, decreased efficiency, and accelerated belt wear. Belt tensioners help reduce slippage by maintaining the appropriate tension in the belt. The tensioner applies sufficient force to keep the belt tightly engaged with the pulleys, preventing slip under normal operating conditions. This enhanced grip improves power transmission efficiency, ensures accurate timing in timing belt applications, and minimizes the risk of belt-related issues caused by slippage.

Proper tension and reduced slippage provided by belt tensioners contribute to an extended lifespan of belts. By maintaining the correct tension, tensioners minimize the stress and strain on the belt, reducing the likelihood of premature wear or failure. They help distribute the load evenly across the belt, reducing localized wear and increasing the overall durability of the belt. Additionally, by preventing belt slippage, tensioners minimize the frictional forces that can cause heat buildup and accelerated belt degradation. This results in improved belt life and reduced maintenance costs.

Belt tensioners help reduce the need for frequent belt adjustments and maintenance. With a properly tensioned belt, the risk of belt-related issues such as misalignment, excessive wear, or premature failure is minimized. This reduces the frequency of belt replacements or adjustments, resulting in reduced maintenance downtime and costs. Belt tensioners also contribute to overall system reliability by ensuring consistent performance, reducing the need for frequent manual interventions or re-tensioning.

Improper tension or slippage in belts can lead to excessive noise and vibrations in the system. Belt tensioners help mitigate these issues by maintaining the correct tension and reducing slippage. By ensuring proper belt engagement, tensioners minimize noise generation and vibration levels, enhancing the overall comfort and performance of the system.

In summary, belt tensioners enhance the overall efficiency and lifespan of belts by maintaining optimal tension, compensating for belt stretch, reducing slippage, improving belt life, reducing maintenance needs, and minimizing noise and vibrations. By ensuring proper tension and reducing wear, belt tensioners contribute to efficient power transmission, extended belt life, and improved reliability of belt-driven systems in various applications.

Can you explain the principles behind belt tensioner operation and adjustment?

Belt tensioners operate based on a set of principles aimed at maintaining the proper tension in belts. They are designed to apply and control the tension in the belt drive system, ensuring optimal performance and longevity. Here's a detailed explanation of the principles behind belt tensioner operation and adjustment:

- Tensioning Mechanism:

- Proper Tension Range:

- Belt Deflection:

- Adjustment and Maintenance:

- Monitoring and Inspection:

- Consideration of Environmental Factors:

Belt tensioners typically consist of a mechanical mechanism that applies force to the belt, adjusting its tension. The tensioning mechanism can vary depending on the specific design and application. Common types of tensioners include spring-loaded tensioners, hydraulic tensioners, and automatic tensioners. These mechanisms are designed to exert a specific amount of force on the belt, maintaining the desired tension level.

Each belt has a specific tension range recommended by the manufacturer. This range ensures optimal power transmission, minimal slippage, and reduced wear. Belt tensioners are adjusted to operate within this recommended tension range. It is important to follow the manufacturer's guidelines or specifications to determine the appropriate tension for a specific belt and application.

During operation, belts experience a certain degree of deflection or sag between the pulleys. Belt tensioners account for this deflection and compensate for it by applying the appropriate tension. The tensioner mechanism is adjusted to ensure that the belt maintains the desired tension even when subjected to deflection. This helps to prevent excessive slack or tightness in the belt, optimizing power transmission and minimizing wear.

Belt tensioners require periodic adjustment and maintenance to ensure optimal performance. The adjustment process involves inspecting the belt tension, evaluating its deflection, and making necessary adjustments to bring it within the recommended tension range. Tensioners may feature adjustment bolts, nuts, or other mechanisms that allow for precise tension adjustments. It is essential to follow the manufacturer's instructions and use appropriate tools to adjust the tensioner correctly.

Regular monitoring and inspection of belt tensioners are crucial for their effective operation. This involves visually examining the tensioner for signs of wear, damage, or misalignment. It is also important to check the belt tension regularly using appropriate tension measuring tools or techniques. By monitoring the tensioner and the belt's condition, any issues can be identified and addressed promptly, ensuring optimal tension and preventing potential problems.

Environmental factors such as temperature, humidity, and operating conditions can influence belt tension. Belt tensioners should be adjusted and maintained considering these factors. For example, temperature changes can cause the belt to expand or contract, affecting its tension. Tensioners may incorporate features to compensate for such variations, ensuring consistent tension under different environmental conditions.

In summary, belt tensioner operation and adjustment are based on principles that involve applying the appropriate tension to the belt, accounting for deflection, operating within the recommended tension range, and considering environmental factors. Tensioners are adjusted and maintained to ensure optimal power transmission, minimize wear, and prevent issues such as slippage or excessive tension. Regular monitoring and inspection of tensioners and belts are essential for their reliable operation and longevity.

Can you describe the various types of belt tensioners, such as automatic or manual tensioners?

There are various types of belt tensioners available, each designed to fulfill specific requirements in maintaining belt tension. Here's a description of the different types of belt tensioners:

- Manual Belt Tensioners:

- Automatic Belt Tensioners:

- Hydraulic Belt Tensioners:

- Eccentric Belt Tensioners:

- Idler Pulley Tensioners:

Manual belt tensioners are the most basic type and require manual adjustment to set and maintain the desired tension. They typically consist of an adjustable arm or bracket that can be moved to increase or decrease the tension in the belt. Manual tensioners are commonly used in applications where tension adjustments are infrequent or can be easily accessed for manual adjustment. They are simple, cost-effective, and widely used in various industries.

Automatic belt tensioners, also known as self-adjusting or spring-loaded tensioners, are designed to maintain the proper tension automatically. They incorporate a spring mechanism that applies constant tension to the belt, compensating for belt elongation and wear over time. Automatic tensioners are commonly used in applications where frequent manual adjustments are impractical or where consistent tension control is essential. They provide convenience, minimize maintenance requirements, and ensure optimal tension without the need for manual intervention.

Hydraulic belt tensioners utilize hydraulic pressure to maintain belt tension. They consist of a hydraulic cylinder or piston that applies force to the tensioner arm, adjusting the tension in the belt. Hydraulic tensioners are commonly used in applications with high load requirements or variable operating conditions. They provide precise tension control, can compensate for changes in temperature and load, and are often employed in heavy-duty industrial machinery and automotive applications.

Eccentric belt tensioners use an eccentric mechanism to adjust the tension in the belt. They typically feature an eccentric pulley or roller that can be rotated to increase or decrease the tension. Eccentric tensioners are commonly used in applications where precise tension adjustments are required, such as high-performance engines or systems with specific belt tension specifications. They offer fine-tuning capabilities and are often found in automotive racing, performance tuning, and specialized machinery.

Idler pulley tensioners, also known as fixed tensioners or idler pulley assemblies, are a type of belt tensioner that utilizes an idler pulley to maintain tension. They are typically positioned on the slack side of the belt, providing guidance and tension control. Idler pulley tensioners are commonly used in applications where a fixed tension is desired, and the tensioning capability is provided by other components in the system, such as an automatic tensioner or an adjustable drive pulley.

In addition to these types, there are also specialized belt tensioners designed for specific applications or industries, such as torsional vibration dampers used in automotive engines to reduce vibrations, or belt tensioners with built-in dampening mechanisms to minimize noise in certain applications.

Overall, the choice of belt tensioner depends on factors such as the application requirements, load conditions, frequency of tension adjustments, and the desired level of automation and control. Selecting the appropriate type of belt tensioner is crucial to maintaining optimal belt tension and ensuring the efficient and reliable operation of belt-driven systems.

editor by CX 2023-11-13

China Standard Truck Engine Parts Belt Tensioner 2117895 for CZPT 345c 345D 349d E345c cv axle puller

Product Description

Product Description

1. We are a professional manufactory product belt tensioner for truck and passenger car.

2. Advantage:

1)Reliable and durable, Strict quality control.

2))FOB\CIF\C&F price.

3)Small MOQ.

4)Specialized in belt tensioner.

5)Wholesale for auto truck parts.

6)Supply package.

3. Packing:

1) OUCHAI packing

2) Neutral packing

3) customer request

4. Shipping:

1. By sea, DHL, FedEx, ect.

2. Within 15 days after receiving 30% deposit

About us

HangZhou OUCHAI TECHNOLOGY CO.,LTD is located in Kunyang Nailali Industrial Zone, Xihu (West Lake) Dis., HangZhou. Our factory is a professional manufacturer of producing belt tensioner with designing and selling.

Our company was founded in 2014, with RMB 3 million registered capital, and covers an area 2000 square meters. There are 30 workers in our factory, including 2 engineers and 6 technicians.

Our company fully implement IATF16949 quality management system and own the advanced production equipment, such as CNC lathe, punching machine, die-casting machine, assembly line and testing equipment.

Our products mainly exported to European, America and South East, and deeply praised by customers. We always adhere to the principle of "integrity is foundation, quality is first, CZPT cooperation" and we'll move forward all the way.

.

| Ouchai No. | Oem NO. | Other Ref. | Application | Size |

| OC-CA015 | 2117895 | DAYCO 89439 | CATERPILLAR | 76*46 |

Detailed Photos

| After-sales Service: | 1year |

|---|---|

| Warranty: | 1year |

| Car Make: | Caterpillar |

| Samples: |

US$ 50/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

How do belt tensioners enhance the overall efficiency and lifespan of belts in various applications?

Belt tensioners play a crucial role in enhancing the overall efficiency and lifespan of belts in various applications. They are designed to maintain proper tension in the belt, ensuring optimal power transmission, minimizing slippage, and reducing wear. Here's a detailed explanation of how belt tensioners enhance efficiency and lifespan:

- Optimal Tension:

- Compensating for Belt Stretch:

- Reduced Slippage:

- Improved Belt Life:

- Reduced Maintenance:

- Noise and Vibration Reduction:

Belt tensioners are responsible for maintaining the correct tension in the belt. Proper tension is essential for efficient power transmission and preventing belt slippage. By applying the right amount of tension, belt tensioners ensure that the belt remains securely engaged with the pulleys, allowing for efficient transfer of power. This optimal tension minimizes energy losses, improves system efficiency, and reduces the risk of premature belt wear or failure due to inadequate tension.

Belts can stretch over time due to various factors such as normal wear, temperature changes, or load variations. Belt tensioners are designed to compensate for belt stretch by automatically adjusting the tension as needed. This feature helps maintain consistent belt tension and ensures proper power transmission, even as the belt elongates over its service life. By compensating for belt stretch, tensioners prevent slack in the belt, reduce the risk of belt jumping or misalignment, and extend the lifespan of the belt.

Slippage between the belt and the pulleys can lead to power loss, decreased efficiency, and accelerated belt wear. Belt tensioners help reduce slippage by maintaining the appropriate tension in the belt. The tensioner applies sufficient force to keep the belt tightly engaged with the pulleys, preventing slip under normal operating conditions. This enhanced grip improves power transmission efficiency, ensures accurate timing in timing belt applications, and minimizes the risk of belt-related issues caused by slippage.

Proper tension and reduced slippage provided by belt tensioners contribute to an extended lifespan of belts. By maintaining the correct tension, tensioners minimize the stress and strain on the belt, reducing the likelihood of premature wear or failure. They help distribute the load evenly across the belt, reducing localized wear and increasing the overall durability of the belt. Additionally, by preventing belt slippage, tensioners minimize the frictional forces that can cause heat buildup and accelerated belt degradation. This results in improved belt life and reduced maintenance costs.

Belt tensioners help reduce the need for frequent belt adjustments and maintenance. With a properly tensioned belt, the risk of belt-related issues such as misalignment, excessive wear, or premature failure is minimized. This reduces the frequency of belt replacements or adjustments, resulting in reduced maintenance downtime and costs. Belt tensioners also contribute to overall system reliability by ensuring consistent performance, reducing the need for frequent manual interventions or re-tensioning.

Improper tension or slippage in belts can lead to excessive noise and vibrations in the system. Belt tensioners help mitigate these issues by maintaining the correct tension and reducing slippage. By ensuring proper belt engagement, tensioners minimize noise generation and vibration levels, enhancing the overall comfort and performance of the system.

In summary, belt tensioners enhance the overall efficiency and lifespan of belts by maintaining optimal tension, compensating for belt stretch, reducing slippage, improving belt life, reducing maintenance needs, and minimizing noise and vibrations. By ensuring proper tension and reducing wear, belt tensioners contribute to efficient power transmission, extended belt life, and improved reliability of belt-driven systems in various applications.

How do innovations and advancements in belt tensioner technology impact their use?

Innovations and advancements in belt tensioner technology have a significant impact on their use, enhancing performance, reliability, and versatility. These advancements introduce new features, improve functionality, and address specific challenges associated with belt-driven systems. Here's a detailed explanation of how innovations and advancements in belt tensioner technology impact their use:

- Improved Tensioning Mechanisms:

- Enhanced Durability:

- Increased Compatibility:

- Noise and Vibration Reduction:

- Advanced Monitoring and Diagnostic Capabilities:

- Integration with System Controls:

New tensioning mechanisms and designs have been developed to provide more precise and efficient tension control. Innovations such as automatic tensioners or self-adjusting tensioners utilize advanced mechanisms that can continuously monitor and adjust the tension in real-time. This improves the overall performance and reliability of belt-driven systems, as the tension can be accurately maintained even under varying loads and operating conditions.

Advancements in materials and manufacturing techniques have contributed to the development of more durable belt tensioners. High-strength alloys, advanced polymers, and specialized coatings are used to increase the resistance to wear, corrosion, and fatigue. These improvements extend the service life of belt tensioners, reducing the frequency of maintenance and replacement and improving the overall reliability of belt-driven systems.

Innovations in belt tensioner technology have led to increased compatibility with a wide range of belt drive systems. Manufacturers have developed adjustable tensioners that can accommodate different belt widths, profiles, and types. This versatility allows for easier integration and replacement of tensioners in various industrial or automotive applications, reducing the need for custom solutions and simplifying maintenance and repairs.

New technologies and designs have been introduced to minimize noise and vibration generated by belt tensioners. Innovative damping materials, improved bearing systems, and optimized geometries help reduce noise and vibration levels, resulting in quieter and smoother operation. This is particularly beneficial in applications where noise reduction and operator comfort are essential.

Advancements in belt tensioner technology have facilitated the integration of monitoring and diagnostic capabilities. Smart tensioners equipped with sensors and connectivity features can provide real-time data on tension levels, temperature, and other operating parameters. This enables predictive maintenance, early fault detection, and optimized performance. By leveraging data-driven insights, operators can make informed decisions, improve system efficiency, and prevent unexpected failures.

Innovative belt tensioner technologies can be integrated with system controls and automation platforms. This allows for seamless integration into larger control systems, enabling automated tension adjustments, synchronization with other components, and coordinated operation. The integration of belt tensioners with system controls enhances system performance, efficiency, and overall productivity.

In summary, innovations and advancements in belt tensioner technology have a significant impact on their use. These advancements improve tensioning mechanisms, enhance durability, increase compatibility, reduce noise and vibration, enable advanced monitoring and diagnostics, and facilitate integration with system controls. By incorporating these innovations, belt tensioners offer improved performance, reliability, and versatility, leading to enhanced efficiency and reduced maintenance requirements in various industrial and automotive applications.

Can you describe the various types of belt tensioners, such as automatic or manual tensioners?

There are various types of belt tensioners available, each designed to fulfill specific requirements in maintaining belt tension. Here's a description of the different types of belt tensioners:

- Manual Belt Tensioners:

- Automatic Belt Tensioners:

- Hydraulic Belt Tensioners:

- Eccentric Belt Tensioners:

- Idler Pulley Tensioners:

Manual belt tensioners are the most basic type and require manual adjustment to set and maintain the desired tension. They typically consist of an adjustable arm or bracket that can be moved to increase or decrease the tension in the belt. Manual tensioners are commonly used in applications where tension adjustments are infrequent or can be easily accessed for manual adjustment. They are simple, cost-effective, and widely used in various industries.

Automatic belt tensioners, also known as self-adjusting or spring-loaded tensioners, are designed to maintain the proper tension automatically. They incorporate a spring mechanism that applies constant tension to the belt, compensating for belt elongation and wear over time. Automatic tensioners are commonly used in applications where frequent manual adjustments are impractical or where consistent tension control is essential. They provide convenience, minimize maintenance requirements, and ensure optimal tension without the need for manual intervention.

Hydraulic belt tensioners utilize hydraulic pressure to maintain belt tension. They consist of a hydraulic cylinder or piston that applies force to the tensioner arm, adjusting the tension in the belt. Hydraulic tensioners are commonly used in applications with high load requirements or variable operating conditions. They provide precise tension control, can compensate for changes in temperature and load, and are often employed in heavy-duty industrial machinery and automotive applications.

Eccentric belt tensioners use an eccentric mechanism to adjust the tension in the belt. They typically feature an eccentric pulley or roller that can be rotated to increase or decrease the tension. Eccentric tensioners are commonly used in applications where precise tension adjustments are required, such as high-performance engines or systems with specific belt tension specifications. They offer fine-tuning capabilities and are often found in automotive racing, performance tuning, and specialized machinery.

Idler pulley tensioners, also known as fixed tensioners or idler pulley assemblies, are a type of belt tensioner that utilizes an idler pulley to maintain tension. They are typically positioned on the slack side of the belt, providing guidance and tension control. Idler pulley tensioners are commonly used in applications where a fixed tension is desired, and the tensioning capability is provided by other components in the system, such as an automatic tensioner or an adjustable drive pulley.

In addition to these types, there are also specialized belt tensioners designed for specific applications or industries, such as torsional vibration dampers used in automotive engines to reduce vibrations, or belt tensioners with built-in dampening mechanisms to minimize noise in certain applications.

Overall, the choice of belt tensioner depends on factors such as the application requirements, load conditions, frequency of tension adjustments, and the desired level of automation and control. Selecting the appropriate type of belt tensioner is crucial to maintaining optimal belt tension and ensuring the efficient and reliable operation of belt-driven systems.

editor by CX 2023-11-13

China Diesel Marine Engine Parts Belt Tensioner Pulley 3974102 3973820 for 4b3.9 B4.5 6b5.9 B6.7 Isb Qsb Engine pulley assembly

Merchandise Description

Our Rewards

We has been providing real and high top quality starters at the most affordable achievable cost in China, and obtained a high popularity from our clientele thanks to the trustworthy good quality, aggressive value and on-time shipping and delivery.

1.Sturdy and large Good quality.

two.Nice-looking packing.

three.Prompt delivery.

four.Broad assortment of components for much more versions offered.

5.Most aggressive wholesale charges.

six.One particular stop getting support presented.

| Part Name | Belt Tensioner | Component NO | 3973820 |

| Product | ISB6.seven | Quality | Authentic AND AFTERMARKET Accessible |

| PACKING | STHangZhouRD Package deal | WARRENTY | 6MONTHS |

| MOQ | 1PC | PAYMENT Term | T/T, WERTERN UNION, L/C |

| Shipping TIME | 7DAYS | FOB PORT | HangZhou,HangZhou,ZheJiang , HangZhou. And so on |

Certifications

Firm Profile

FAQ

Issue 1:How to buy motor spare parts? Initial of all, you should tell us the portion variety of the elements you need to have. We will provide the very same parts as yours. Secondly, if you never know the element variety, please offer components identify and motor series number, then we will verify the part amount through engine series number.

Issue 2:How long is the shipping time? For total motor and Energy models , we require to prepare creation in accordance to the get, our basic delivery time is fifteen-thirty times. For spare elements , our common shipping and delivery time is 3-ten days.

Issue 3:How to arrange supply? Considering the massive quantity and weight of our merchandise, to help save the delivery value, we usually suggest ship to your nearest port For little objects and urgent orders, we can also give air cargo and deliver items to the airport in your town or your business address.

Issue 4:How about Payment Methods? We suggest thirty/70,T/T payment strategy: 30 % down payment on placement of the purchase, with the remaining 70% due on shipment. Issue 5:How about Packing Methods? Usually we use wooden bins for packaging or we can pack it according to your particular wants.

|

US $67-420 / Piece | |

1 Piece (Min. Order) |

###

| Certification: | CCC, ISO9001, CE, RoHS |

|---|---|

| Standard Component: | Standard Component |

| Technics: | Casting |

| Warranty: | 6 Months |

| Engine Type: | Diesel Engine |

| Quality: | 100% New |

###

| Samples: |

US$ 2/Piece

1 Piece(Min.Order) |

|---|

###

| Customization: |

Available

|

|---|

###

| PART NAME | Belt Tensioner | PART NO | 3973820 |

| Model | ISB6.7 | QUALITY | GENUINE AND AFTERMARKET AVAILABLE |

| PACKING | STANDARD PACKAGE | WARRENTY | 6MONTHS |

| MOQ | 1PC | PAYMENT TERM | T/T, WERTERN UNION, L/C |

| DELIVERY TIME | 7DAYS | FOB PORT | GUANGZHOU,SHENZHEN,SHANGHAI, NINGBO. ETC |

|

US $67-420 / Piece | |

1 Piece (Min. Order) |

###

| Certification: | CCC, ISO9001, CE, RoHS |

|---|---|

| Standard Component: | Standard Component |

| Technics: | Casting |

| Warranty: | 6 Months |

| Engine Type: | Diesel Engine |

| Quality: | 100% New |

###

| Samples: |

US$ 2/Piece

1 Piece(Min.Order) |

|---|

###

| Customization: |

Available

|

|---|

###

| PART NAME | Belt Tensioner | PART NO | 3973820 |

| Model | ISB6.7 | QUALITY | GENUINE AND AFTERMARKET AVAILABLE |

| PACKING | STANDARD PACKAGE | WARRENTY | 6MONTHS |

| MOQ | 1PC | PAYMENT TERM | T/T, WERTERN UNION, L/C |

| DELIVERY TIME | 7DAYS | FOB PORT | GUANGZHOU,SHENZHEN,SHANGHAI, NINGBO. ETC |

Pulley Type

There are several types of pulleys. These include fixed pulleys, load multipliers and movable pulleys. Below is a description of each pulley type. A load multiplier is a special type of pulley with multiple wheels for increased lifting capacity. It is used in a wide range of applications including power transmission and construction. Some common uses of pulleys are listed below.

moving pulley

Movable pulleys work by transferring the weight of a load to another object of the same mass. Since a live pulley is inherently frictionless and weightless, the force required to lift a load with it is the same as the weight of the load. This principle applies to tall buildings and residences. It is an excellent choice for lifting heavy objects such as furniture and washing machines.

A pulley is a mechanical device with a wheel that rotates on a shaft. The axle is attached to the wheel and is usually fixed. The movable pulley can be fixed or movable, both of which can change the direction of the force on the rope. Some pulleys can also change the magnitude and direction of the force. They are ideal for a variety of applications, from lifting heavy objects to transporting objects.

Another type of movable pulley works by transmitting force to another object. It has a free axis and the total force provided by the rope tension is balanced. Since the tension on the rope is constant in each segment, pulling one end of the rope will double the force on the shaft, resulting in two mechanical advantages. This mechanical advantage is the main reason why movable pulleys are so versatile.

Another form of moving pulley is called a KWL diagram. The KWL diagram summarizes the basic concepts of the drive wheel. KWL diagrams are an excellent way to assess a student's understanding of the concepts discussed in the course. Word questions are a great way to check whether students understand concepts. When students answer the word questions correctly, the answer is yes!

Fixed wheel pulley

If you need to move heavy objects, a single fixed wheel pulley is not a good choice. Using a single fixed pulley might be similar to using a handbag, but it's not very convenient. This type of pulley system relies on friction to transmit motion. As a result, it can slip and isn't always reliable. Fortunately, you can find other options that work just as well.

Fixed pulleys are the most basic type of pulley. They consist of grooved wheels and ropes attached to objects. These pulleys make lifting easier. Because the rope or cable only moves in one direction, the movement of the object feels lighter. And they are also easy to install. However, before you buy a fixed wheel pulley, make sure it is strong enough to support the weight of the load.